Blog Center

Blog

After the heat treatment of the bearing ring before finishing, the surface hardness is greatly improved. Other machining methods such as turning can not meet the requirements of bearing machining accuracy, and can not meet the requirements of mass production. Therefore, it must be ground during finishing.

In the production of bearings, the grinding labor accounts for about 60% of the total labor. For high-precision bearings, the grinding ratio is larger, and the grinding of the bearings is precision machining. The unit of size and geometric accuracy is μm. Bearings of different precision grades have different processing steps and technical requirements for the ferrule parts during the grinding process.

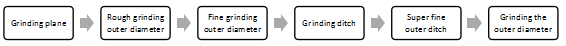

In order to meet the market demand, our company has formed its own bearing grinding system for many years. The P0 grade bearing adopts the small cycle grinding method because the precision grade is ordinary grade. Coatfor

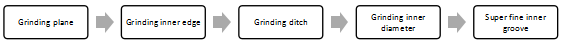

Inner sleeve is

The accuracy requirement of P5 grade products is relatively high, and the service life of bearings is also high.Therefore, a large cycle of grinding is used. Coat for

Inner sleeve is

By increasing the tempering stability and increasing the number of grinding times, the service life and accuracy of the bearing are guaranteed. At present, this process has become a symbol of bearings and affects the entire bearing industry.